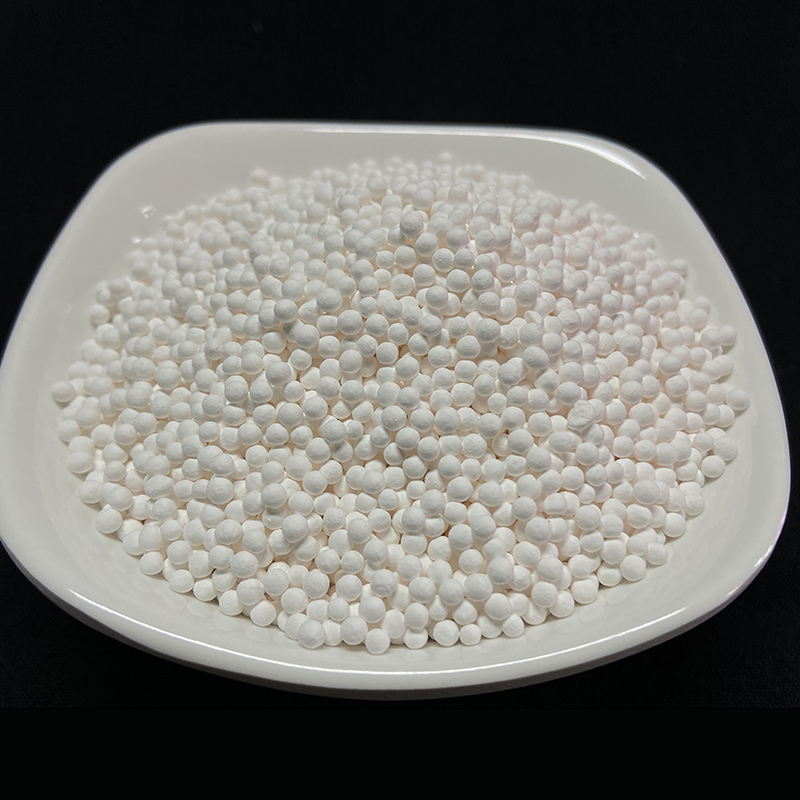

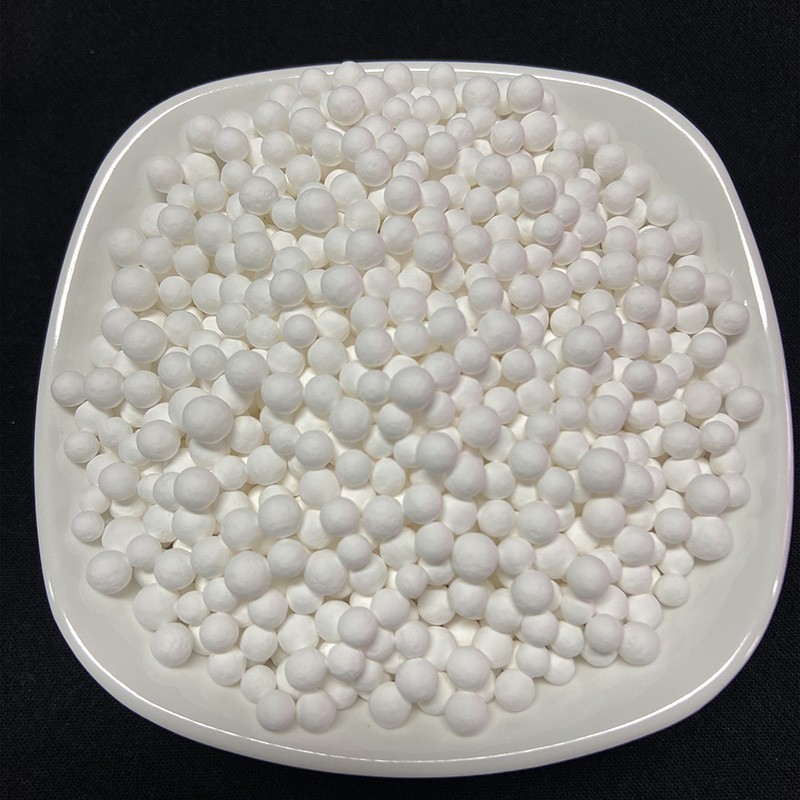

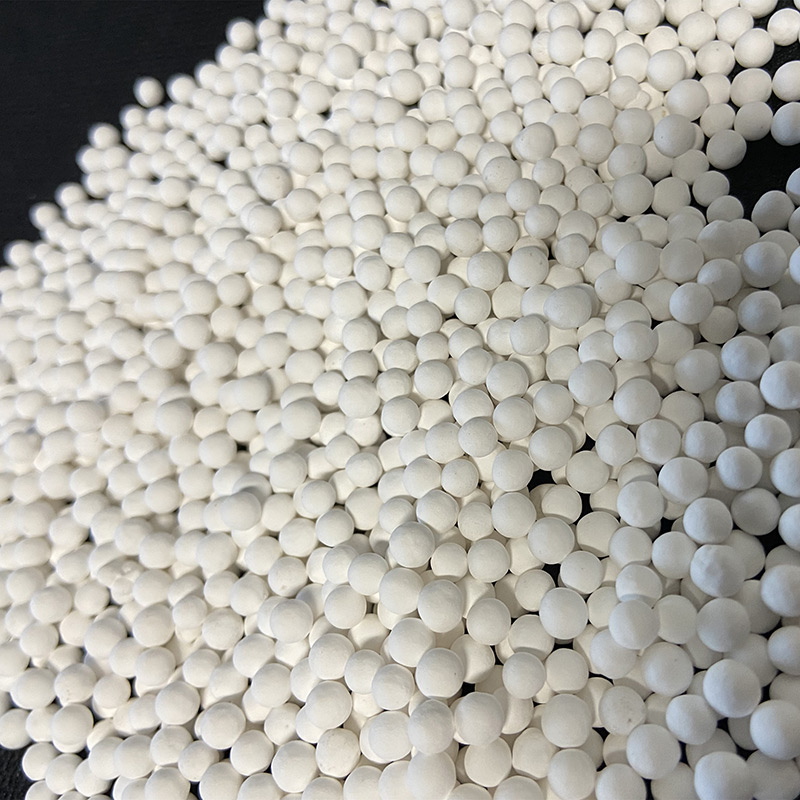

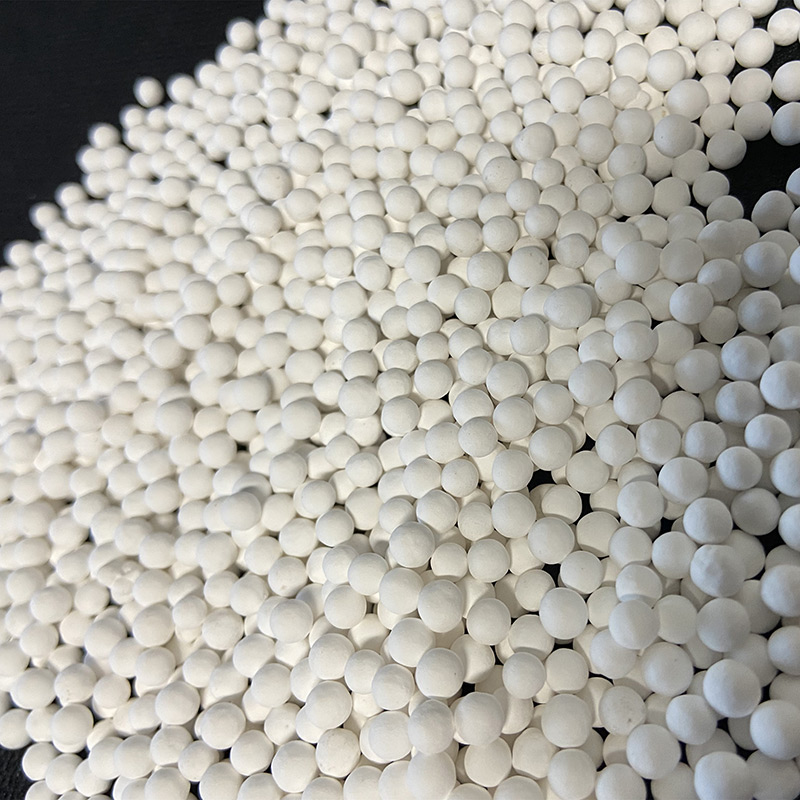

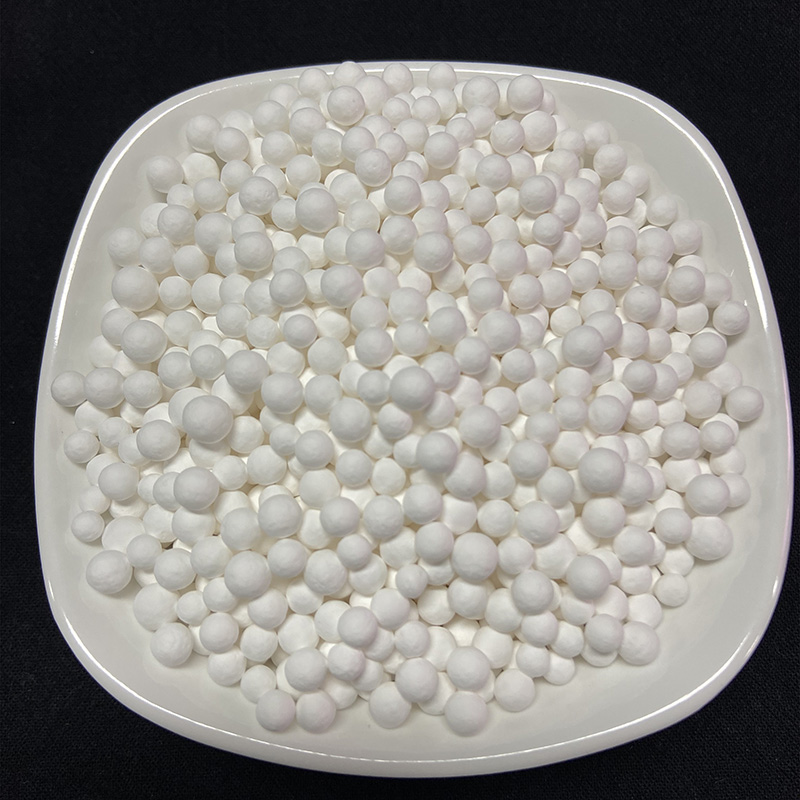

Alumina Ceramic Filler High Alumina Inert Ball/99% mpira wa alumina ceramic

Zakuthupi Ndi Zamankhwala Za Mipira Ya Ceramic Inert

| Zakuthupi ndi mankhwala a inert ceramic mipira | |||||||

| Chinthu | Al2O3% | 60 | 70 | 80 | 90 | 95 | 99 |

| Fe2O3% | ≤0.9 | ≤0.8 | ≤0.6 | ≤0.4 | ≤0.3 | ≤0.1 | |

| Zigawo zotsalira zikhoza kutsimikiziridwa kupyolera mu zokambirana pakati pa wogulitsa ndi wogula ngati kuli kofunikira. | |||||||

| kuyamwa madzi, % | 3 ± 1, Itha kuzindikirikanso ndi kukambirana pakati pa wogulitsa ndi wogula | ||||||

| gawo,kg/m³ | 2.5-3.0 | 2.7-3.2 | 2.9-3.2 | ≥3.1 | ≥3.2 | ≥3.4 | |

| Kuchulukana kwakukulu, kg/m³ | 1400-1550 | 1400-1650 | 1500-1800 | 1700-1950 | 1800-1950 | ≥1900 | |

| Fumbi, ming'alu kapena kusweka | Chikwama chimodzi ndi chochepera 5% | ||||||

| Kupatuka kwa kukula | Chigawo chofanana, chiŵerengero cha kukula kwakukulu mpaka kakang'ono kwambiri kagawo kakang'ono ka ceramic sidutsa 1.2 | ||||||

| Dimensional kulolerana | ≤10 mm | ±1.0 | |||||

| 11-25 mm | ±1.5 | ||||||

| 26-50 mm | ±2.0 | ||||||

| ≥50 mm | ±3.0 | ||||||

| Mphamvu yakugwa kwaulere | Mtengo wosatayika ≥99% | ||||||

| Compressive mphamvu | φ3 | ≥250 | ≥300 | ≥350 | ≥400 | ≥500 | ≥500 |

| φ6 | ≥800 | ≥1000 | ≥1000 | ≥1200 | ≥1500 | ≥1500 | |

| φ8 | ≥1500 | ≥1600 | ≥1800 | ≥2000 | ≥2500 | ≥2500 | |

| φ10 | ≥2000 | ≥2500 | ≥2800 | ≥3000 | ≥3500 | ≥3500 | |

| φ13 | ≥3000 | ≥3000 | ≥3500 | ≥4000 | ≥5000 | ≥5000 | |

| φ16 | ≥3500 | ≥4000 | ≥4500 | ≥5000 | ≥6000 | ≥7000 | |

| φ20 | ≥6000 | ≥6000 | ≥7000 | ≥8000 | ≥10000 | ≥12000 | |

| φ25 | ≥7000 | ≥7000 | ≥8000 | ≥10000 | ≥15000 | ≥17000 | |

| φ30 | ≥8000 | ≥9000 | ≥10000 | ≥12000 | ≥17000 | ≥19000 | |

| φ38 | ≥10000 | ≥12000 | ≥13000 | ≥15000 | ≥20000 | ≥22000 | |

| φ50 | ≥12000 | ≥14000 | ≥16000 | ≥18000 | ≥22000 | ≥26000 | |

| φ75 | ≥16000 | ≥18000 | ≥20000 | ≥22000 | ≥25000 | ≥30000 | |

| 50-75 | 55-75 | 60-80 | ≥80 | ≥82 | ≥85 | ||

| Mavalidwe % | ≤2 | ≤1 | |||||

| kusungunuka kwa asidi, % | ≤6 | ||||||

| Alkalinity,% | ≥77 | ≥85 | ≥90 | ≥92 | ≥95 | ≥97 | |

| Refractoriness, ℃ | ≥400 | ≥500 | ≥700 | ≥1000 | ≥1000 | ≥1000 | |

| Kugonjetsedwa ndi kusiyana kwadzidzidzi kuthamanga | Mlingo wosawononga ≥ 99%, palibe kusintha kwa mphamvu yopondereza ndi kupanikizika pambuyo pa kusintha kwadzidzidzi ndi zosakwana 25% | ||||||

| Kugonjetsedwa ndi kusintha kwadzidzidzi kutentha | Mtengo wosatayika≥99% | ||||||

| Phukusi | Kupaka ng'oma zachitsulo | Odzaza ndi ng'oma zachitsulo, zosindikizidwa ndi PP kapena matumba apulasitiki a PE | |||||

| Woven bag phukusi | Amapezeka m'matumba oluka olimba komanso osamva UV | ||||||

| Zindikirani: Deta ya kuchuluka kwachulukidwe ndiyongowona, osati ngati maziko ovomerezeka. | |||||||

Chidziwitso china: Onani Table 5 Pamayamwidwe a Madzi a Mipira Yodzaza 99

| 99 Kudzaza Madzi a Mpira | ||

| 99 filler | awiri | awiri |

| mpukutu kupanga | <25mm | <5% |

| Kupanga makina osindikizira | φ>25mm | <10% |

99.5% Zizindikiro Zaukadaulo

| Al2O3 | ≥99% |

| SiO2 | ≤0.14% |

| Fe2O3 | ≤0.04% |

| CaO +MgO | ≤0.03% |

| TiO2 | ≤0.06% |

| Na2O | ≤0.1% |

| K2O | ≤0.1% |

Physical Index of Chemical Filler Ball

| CONDITION | INDEX |

| kufewetsa katundu (yb/t370-1995) | Deformation pansi pa 0.2mpa pressure ndi yochepera 0.6% |

| Thermal shock resistance (yb/t376.2-1995) | 1200 ° C mpaka 600 ° C. 10 nthawi popanda pamwamba ming'alu |

| Kusintha kwa mzere (gb/t3997.1-1998) | 1400 ℃ kwa maola 12, mtengo wapamwamba ndi 0.25%, mtengo wapakati ndi wochepera 0.20% |

| Kuchulukana (gb/t2997-2000) | 3.2-3.50 g/cm3 |

| kuphwanya mphamvu | Kumanani opitilira 230 kg / cm2 |

| Zowoneka porosity | 12-18% |

| Kuchulukana kwakukulu | 2.1-2.3g/cm3 |

Chemical Packing Ball Packing

1) kulongedza wamba: polyethylene nsalu thumba ndi ukonde kulemera kwa 25kg, kuphatikiza mphasa

2) zitsulo ng'oma ma CD: 100L zitsulo ng'oma ma CD, mapallet akhoza kuwonjezeredwa